Palm Complex Facilities

Palm Oil Mill

At the capacity of 75 tons of FFB / hour, the palm oil mill is able to consume approximately 1,800 tons of FFB / day to produce CPO which will be sent for refining in the refinery

Product Related:

Refinery and Dryfractionation

At the capacity of 600 tons / day, the palm oil refinery is able to refine CPO to produce RBDPO which is the main feedstock for biodiesel and palm olein production. The RBDPO can then be fed to the 300 tons / day dry fractionation plant to produce palm olein for the consumption of our customers both in the industrial and retail segments.

Product Related:

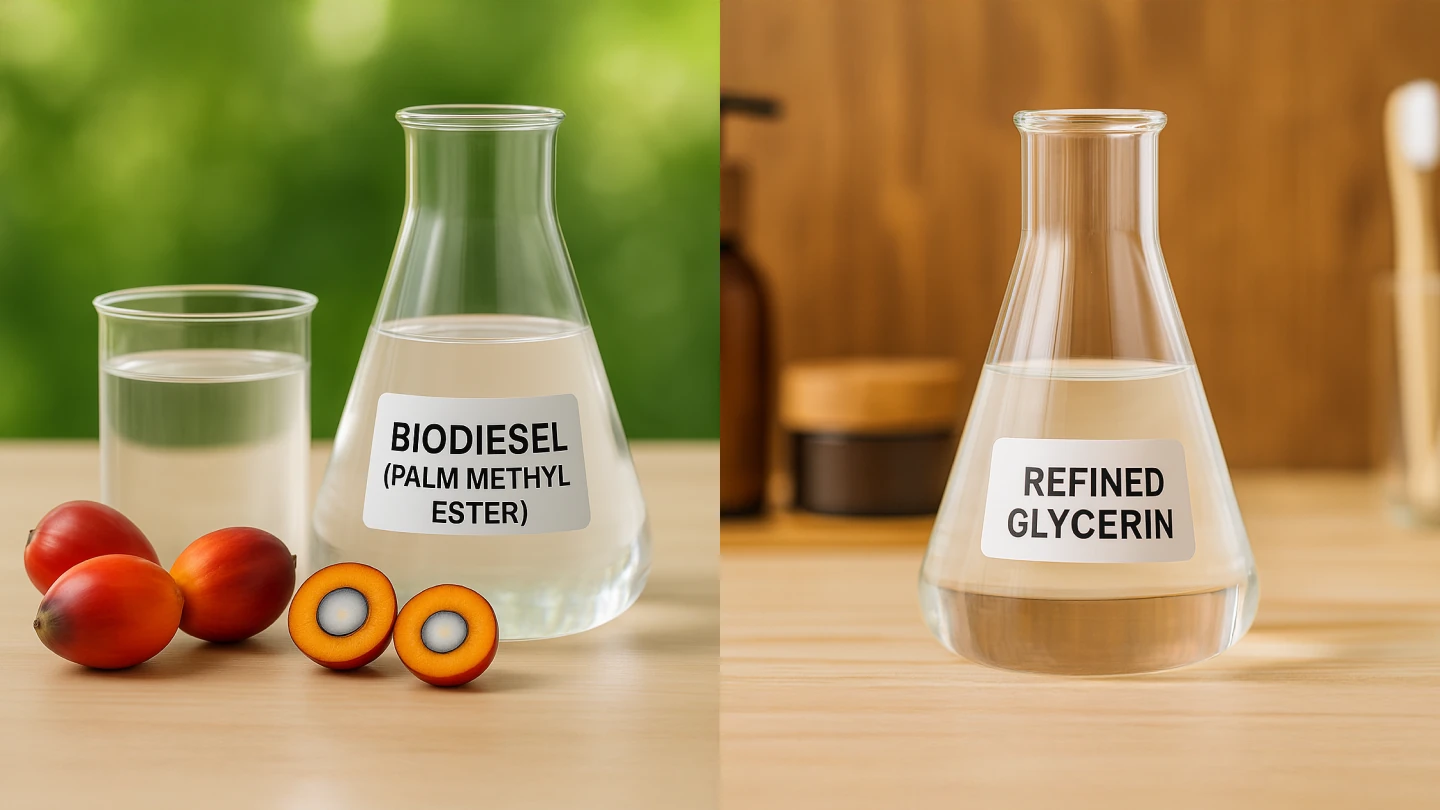

Biodiesel and Glycerin

At the capacity of 45 tons/day, PPP is one of the market leaders in the manufacturing of the highest quality distilled biodiesel in Thailand. the biodiesel plant is able to produce distilled biodiesel at 520,000 litres/day,

where the biodiesel is then supplied to oil refineries and for use in patrol stations nation wide. Crude glycerin which is the by-product of biodiesel production is then distilled into refined glycerin for industrial use such as the production of antifreeze ECH, or for pharmaceutical uses such as creams and capsules manufacturing

Product Related:

Power Plant and High-Pressure Steam Boiler

At a capacity of 7 MW, the power plant utilizes empty fruit bunches (EFB), a by-product of palm oil milling, as its primary biomass feedstock to generate electricity for the plant’s internal operations. In addition, biogas from the palm oil mill is used as feedstock for a 25-ton package steam boiler to produce steam for use across the complex.

Tank Farm

At the capacity of 100,000 tons, our tank farm supports the plant’s production of various goods, and act as a buffer to support the palm oil industry in Thailand.